เครื่องจักรคุณภาพสูง นำเข้าจากประเทศชั้นนำ ต้อง IIT Group เท่านั้นที่ให้คุณมากกว่าบริการ

เพราะบริการที่เป็นเลิศ ต้องมาจากมุมมองของลูกค้า

| (Turning) | (Turning&Milling) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| TCN-3500 L5 | TCN-3500 L10 | TCN-3500CM L5 | TCN-3500CM L10 | ||||||

| Chuck Size | inch | 12 | 10 | 12 | 10 | 10 | 10 | ||

| Type of Turret |

8-Station Turret (Direct-Mount Type) |

10-Station Turret (Direct-Mount Type) |

12-Station Turret (Direct-Mount Type) |

8-Station Turret (Direct-Mount Type) |

10-Station Turret (Direct-Mount Type) |

12-Station Turret (Direct-Mount Type) |

Rotary Tool Type 12-Station Turret |

Rotary Tool Type 12-Station Turret |

|

| Max. Turning Diameter | mm | φ430 | φ460 | φ430 | φ460 | φ370 | φ370 | ||

| Max. Turning Length | mm | 485 | 510 | 985 | 1010 | 465 | 965 | ||

| Bar Capacity 1 | mm | φ88 [OP. φ108] | φ88 [OP. φ108] | φ88 [OP. φ108] | φ88 [OP. φ108] | ||||

| Spindle Speed | min-1 | 2500 [OP. 3000] | 2500 [OP. 3000] | 2500 [OP. 3000] | 2500 [OP. 3000] | ||||

| Rotary Tool Speed | min-1 | - | - | 3600 | 3600 | ||||

| Rapid Traverse Rate | m/min | X : 16 / Z : 24 | X : 16 / Z : 24 | X : 16 / Z : 24 | X : 16 / Z : 24 | ||||

|

Spindle Motor (30 min/continuous) |

kW | 15/11 | 15/11 | 15/11 | 15/11 | ||||

|

Rotary Tool Motor (15 min/continuous) |

kW | - | - | 3.7/11 | 3.7/11 | ||||

| Machine Height | mm | 1802 | 1802 | 1802 | 1802 | ||||

| Required Floor Space | mm | 2000×1768 | 3450×1833 | 2000×1768 | 3450×1833 | ||||

| Machine Weight | kg | 4000 | 5000 | 4100 | 5100 | ||||

| Outside Diameter | mm | φ200 |

| Length | mm | 140 |

| Weight | kg | 10 (×2) |

| Number of Pallets | 10 | |

| Loading Capacity(Per Pallet) | kg | 70 |

| Work Stacking Height | mm | 400 |

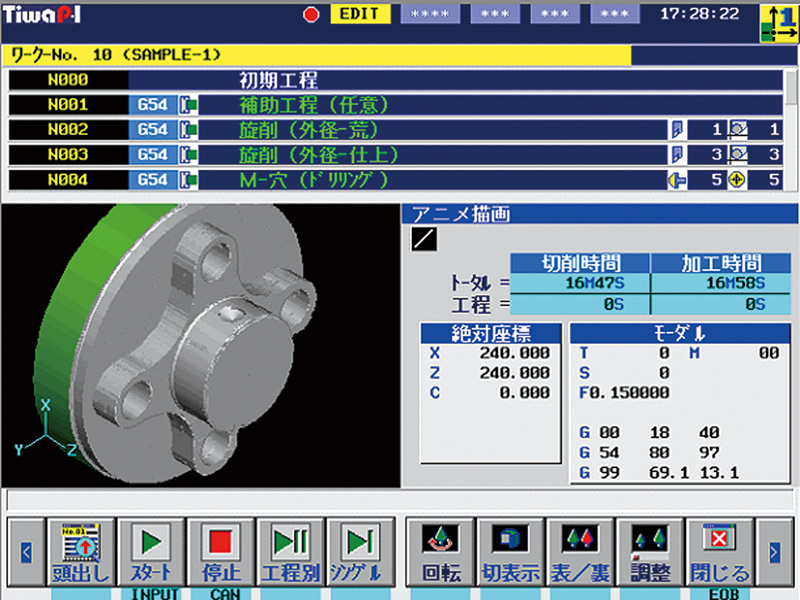

TiwaP-1 is an interactive programming system fully supporting creation, simulation, and execution of machining programs to reduce operator' labor.

Input by the interactive system is easy for the operator to create programs without knowledge of G codes. Check of programs can be done by simulating the cutting results with 3D animation and tool path drawing. In Operation, the machining spindle and the order of process types are automatically recognized to optimally execute spindle control and C-axis zero return.